The Vital Role of Corner Pasting Machines in Streamlining Packaging Processes

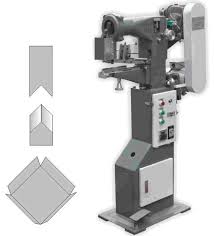

The corner pasting machine, a cornerstone of the packaging industry, plays a critical role in enhancing the efficiency and quality of packaging production lines. Designed to precisely apply adhesive to the corners of boxes and other packaging materials, these machines have revolutionized the way manufacturers approach the assembly process. This brief article explores the significance of corner pasting machines and their impact on the packaging sector.

Efficiency and Precision Combined

Corner pasting machines automate one of the most tedious aspects of packaging production: the application of glue to box corners. By doing so, they not only speed up the production process but also ensure that each application is consistent and precise. This level of accuracy is difficult to achieve manually and is crucial for producing high-quality packaging that meets industry standards.

Reduced Waste and Cost Savings

One of the standout benefits of using corner pasting machines is their contribution to waste reduction. By applying the exact amount of adhesive required, these machines minimize excess glue use, leading to significant material savings over time. Additionally, the automation of the pasting process reduces labor costs, as fewer hands are needed on deck to achieve faster and more reliable production outcomes.

Adaptability to Various Production Needs

Modern corner pasting machines are designed with flexibility in mind. They can accommodate a wide range of materials, sizes, and types of packaging, making them suitable for various applications within the industry. This adaptability allows manufacturers to switch between production runs with minimal downtime, catering to the dynamic demands of the market.

Conclusion