Enhancing Production Efficiency with Advanced Corner Pasting Machines

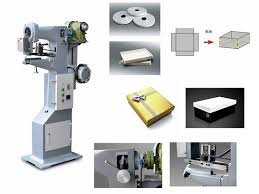

In today’s competitive manufacturing landscape, efficiency and quality are paramount for businesses aiming to thrive. Corner pasting machines, pivotal in the realms of packaging and bookbinding, stand out as indispensable tools for achieving these goals. These sophisticated machines are designed to apply adhesive to the corners of various products like cardboard boxes, book covers, and file folders, ensuring durability and a polished finish. This article delves into how advanced corner pasting machines significantly enhance production efficiency, highlighting their key features and benefits.

The Role of Corner Pasting Machines in Modern Manufacturing

Corner pasting machines automate the process of applying adhesive to product corners, a task that is traditionally labor-intensive and prone to inconsistencies when done manually. By integrating these machines into production lines, manufacturers can maintain a high level of precision and consistency, which is crucial for the structural integrity and aesthetic appeal of the final products. The automation provided by corner pasting machines not only boosts production speed but also significantly reduces the likelihood of human error, leading to more reliable and high-quality output.

Key Features of Advanced Corner Pasting Machines

Modern corner pasting machines are equipped with a plethora of features designed to meet the diverse needs of manufacturers. These include adjustable speed settings, which allow for the accommodation of various production demands and the efficient management of production timelines. Furthermore, many corner pasting machines now offer programmable logic controllers (PLCs) and touchscreen interfaces, enabling precise control over the adhesive application process and easy adjustment for different product sizes and specifications.

Benefits of Implementing Corner Pasting Machines

- Increased Production Efficiency: Advanced corner pasting machines can operate at remarkable speeds, significantly reducing the time required for the adhesive application process. This efficiency enables manufacturers to meet tight deadlines and respond swiftly to market demands.

- Reduced Labor Costs: Automating the corner pasting process minimizes the need for manual labor, thereby reducing labor costs. This automation allows businesses to allocate their human resources to more critical tasks, optimizing overall workforce productivity.

- Enhanced Product Quality: The precision and consistency offered by corner pasting machines ensure that each product meets high-quality standards. This uniformity is essential for maintaining brand reputation and customer satisfaction.

- Sustainability: With an emphasis on minimizing waste, advanced corner pasting machines contribute to sustainable manufacturing practices. By ensuring precise adhesive application, these machines reduce material wastage, aligning with environmental conservation efforts.

Conclusion

The integration of advanced corner pasting machines into production lines marks a significant leap towards operational excellence in the manufacturing sector. These machines not only streamline the adhesive application process but also play a crucial role in enhancing product quality, reducing costs, and promoting sustainability. As manufacturers continue to seek ways to improve efficiency and output quality, the adoption of corner pasting machines will undoubtedly become more widespread, reinforcing their status as essential tools in the modern manufacturing toolkit.