Maximizing the ROI of Corner Pasting Machines in Packaging Production

For packaging manufacturers, investing in corner pasting machines can lead to significant returns on investment (ROI) through improved efficiency, reduced waste, and higher product quality. To maximize the ROI, companies should focus on optimizing the use of their corner pasting machines by regularly maintaining the equipment to prevent downtime, training staff to operate the machines effectively, and continuously monitoring production processes to identify areas for improvement. Additionally, selecting a machine that can be easily integrated with existing systems and adapted to future needs is crucial. By taking these steps, manufacturers can ensure that their corner pasting machines contribute positively to their bottom line, supporting sustainable growth and competitiveness in the packaging industry.

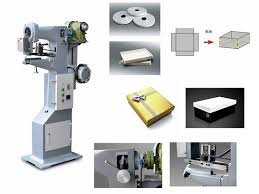

Advancements in Corner Pasting Technology: A Leap Towards Automated Efficiency

The packaging industry is witnessing a revolution with the latest advancements in corner pasting technology. These machines, integral to the production of high-quality packaging, have evolved to offer unprecedented levels of automation and precision. The newest models boast features such as AI-driven control systems, real-time analytics, and automated material handling, significantly reducing the manual labor required and enhancing production line efficiency. This leap towards automated efficiency is not just improving the speed and quality of packaging but is also enabling manufacturers to meet the growing demand for sustainable and innovative packaging solutions. As these technologies continue to mature, they promise to reshape the future of packaging, making it more efficient, sustainable, and adaptable to changing market demands.