Enhancing Structural Integrity: The Role of Corner Pasting Machinery in Packaging Excellence

In the sophisticated world of packaging production, the integrity and aesthetics of the final product are paramount. Corner pasting machinery plays a pivotal role in achieving these attributes by precisely applying adhesive materials to the corners of boxes, ensuring enhanced durability and presentation. This article explores the advancements in corner pasting machinery, its benefits, and the transformative impact it has on the packaging industry.

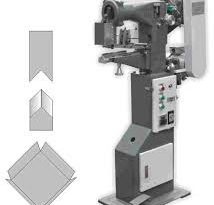

Introduction to Corner Pasting Machinery

Corner pasting machinery is specialized equipment used in the manufacturing of high-quality packaging, particularly for luxury goods, electronics, and fine retail products. These machines automate the application of glue or adhesive strips to the corners of boxes, which is critical for constructing strong and visually appealing packaging.

Key Features of Modern Corner Pasting Machines

Today’s corner pasting machines incorporate a range of advanced features that streamline operations and improve output quality:

- Precision Application: These machines apply adhesives with exact precision, ensuring that each corner is perfectly bonded, which enhances the box’s structural integrity.

- High-Speed Capabilities: Designed to keep up with high-volume production demands, modern corner pasting machines operate at speeds that significantly reduce assembly time.

- Versatility: Capable of handling various box sizes and types, these machines are adaptable to a wide range of packaging needs.

- Automated Adjustments: Equipped with digital control systems, corner pasting machines allow for quick adjustments, minimizing downtime and maximizing efficiency.

Benefits of Using Corner Pasting Machinery

Integrating corner pasting machinery into the packaging process offers several advantages:

- Enhanced Product Durability: Properly pasted corners prevent box deformation and collapse, ensuring that products are protected throughout handling and shipping.

- Improved Aesthetic Appeal: Neat and secure corners enhance the visual appeal of the packaging, which can be crucial for consumer satisfaction and brand image.

- Increased Production Efficiency: Automation speeds up the production process, allowing manufacturers to meet large orders more efficiently.

- Cost-Effectiveness: By reducing the labor-intensive process of manual corner pasting, these machines help lower production costs and reduce human error.

The Impact on the Packaging Industry

Corner pasting machinery has significantly impacted the packaging industry by providing a means to reliably produce high-quality packaging at scale. As the demand for premium packaging solutions increases, particularly in markets where product presentation is critical, the importance of precise and durable corner pasting becomes more pronounced. These machines enable manufacturers to consistently meet quality standards that enhance brand reputation and customer loyalty.

Future Trends in Corner Pasting Technology

The future of corner pasting machinery is likely to see advancements in automation technology, materials science, and adhesive formulations. Innovations may include the use of AI to optimize adhesive application patterns and the development of more sustainable adhesive materials that offer stronger bonds and lower environmental impact. As the packaging industry continues to evolve towards greater sustainability and efficiency, corner pasting machinery will remain at the forefront of technological advancements.

Conclusion

Corner pasting machinery is an essential component of modern packaging production lines, playing a critical role in ensuring that boxes are not only structurally sound but also appealing to consumers. By leveraging the capabilities of advanced corner pasting technology, manufacturers can achieve higher productivity, reduced costs, and superior product quality, making these machines a valuable investment in the competitive packaging market.